What will non condensables in a refrigeration system result in? With this query at the helm, we embark on an illuminating journey to unravel the consequences of non-condensable presence in refrigeration systems. Join us as we delve into the intricacies of system performance, explore the sources and detection methods of non-condensables, and uncover preventative measures to safeguard system integrity.

Non-condensables, like unwelcome guests, disrupt the delicate balance of refrigeration systems, leading to a cascade of undesirable effects. Their presence obstructs heat transfer, hindering the system’s ability to cool efficiently. Moreover, they disrupt refrigerant flow, overworking the compressor and potentially leading to premature failure.

Impact on System Performance

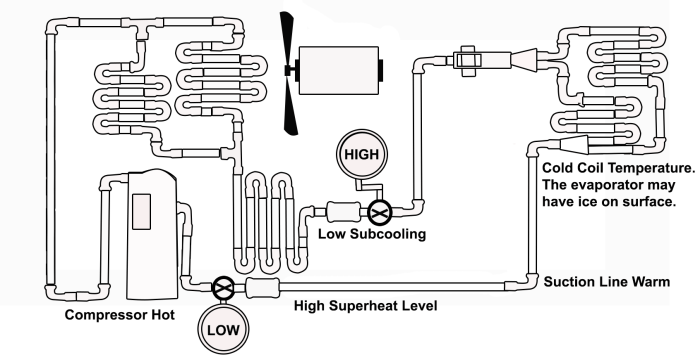

Non-condensables negatively impact a refrigeration system’s performance, reducing its capacity and efficiency. They impair heat transfer in the condenser, causing higher condensing temperatures and reduced refrigerant condensation. This leads to decreased refrigerant flow rate and compressor efficiency, increasing energy consumption and overall system strain.

Effects on Heat Transfer

- Non-condensables accumulate on the condenser surface, forming an insulating layer that hinders heat dissipation.

- The reduced heat transfer efficiency leads to higher condensing temperatures, which in turn decreases the refrigerant’s latent heat of condensation.

Consequences for Refrigerant Flow and Compressor Operation

- Lower refrigerant condensation reduces the mass flow rate through the system.

- The compressor must work harder to maintain the desired cooling capacity, resulting in increased energy consumption.

- Overheating and premature compressor failure can occur if the non-condensable accumulation is severe.

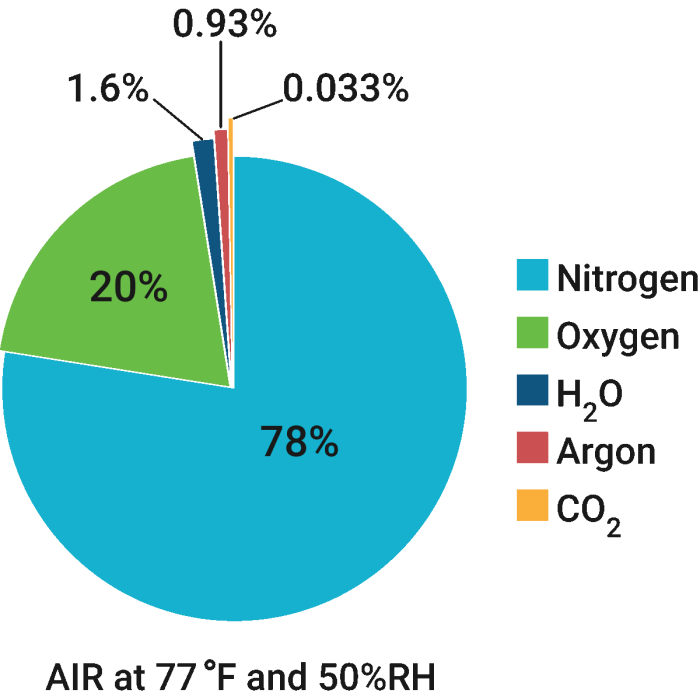

Causes of Non-Condensables

Non-condensables enter refrigeration systems through various sources, including:

Air Leaks

- Leaks in piping, joints, or seals can allow air to enter the system during operation or when it is shut down.

- Air can also be drawn into the system during the charging process if the system is not properly evacuated.

Moisture Ingress

- Moisture can enter the system through leaks in the evaporator coil or during refrigerant charging if the refrigerant is not dry.

- Condensation within the system can also contribute to moisture accumulation.

Consequences of Neglecting Non-Condensable Removal

- Accumulated non-condensables lead to reduced system efficiency and increased energy consumption.

- Overheating and compressor damage can occur due to impaired heat transfer.

- Non-condensables can react with refrigerants, forming corrosive compounds that damage system components.

Detection and Removal Methods: What Will Non Condensables In A Refrigeration System Result In

Detection

- Vacuum testing: Measuring the vacuum level in the system can indicate the presence of non-condensables.

- Refrigerant analysis: Analyzing the refrigerant sample can reveal the presence and concentration of non-condensables.

Removal

- Purging: Using a dry inert gas (e.g., nitrogen) to sweep non-condensables out of the system.

- Evacuating: Creating a vacuum in the system to remove non-condensables.

Selection of Purge Methods

- Small systems: Manual purging with a vacuum pump and inert gas cylinder.

- Large systems: Automated purging systems with mass flow controllers and pressure sensors.

Preventative Measures

Proper System Design and Installation

- Use high-quality components and materials to minimize the risk of leaks.

- Ensure proper sealing of all joints and connections.

- Design the system to minimize moisture ingress, such as using sealed evaporators and moisture-proof insulation.

Leak Detection and Repair

- Regularly inspect the system for leaks using leak detectors or electronic leak testers.

- Promptly repair any leaks identified to prevent further non-condensable ingress.

Non-Condensable Traps and Driers, What will non condensables in a refrigeration system result in

- Non-condensable traps: Devices that physically remove non-condensables from the refrigerant stream.

- Driers: Absorbents that chemically react with moisture and other non-condensables.

FAQ

What are the common sources of non-condensables in refrigeration systems?

Air leaks and moisture ingress are the primary culprits.

How can I detect non-condensables in my refrigeration system?

Vacuum testing and refrigerant analysis are reliable methods for detecting their presence.

What are the preventative measures I can take to minimize non-condensable accumulation?

Proper system design, leak detection and repair, and the use of non-condensable traps and driers are crucial.